Industrial Applications of Sandblasting

Sandblasting, also known as abrasive blasting, is a versatile technique used across various industries for cleaning, deburring, and preparing surfaces. This process involves propelling fine abrasive material under high pressure against a surface to achieve the desired finish. This blog post explores the industrial applications of sandblasting and describes its effectiveness in cleaning, deburring, and surface preparation.

What is Sandblasting?

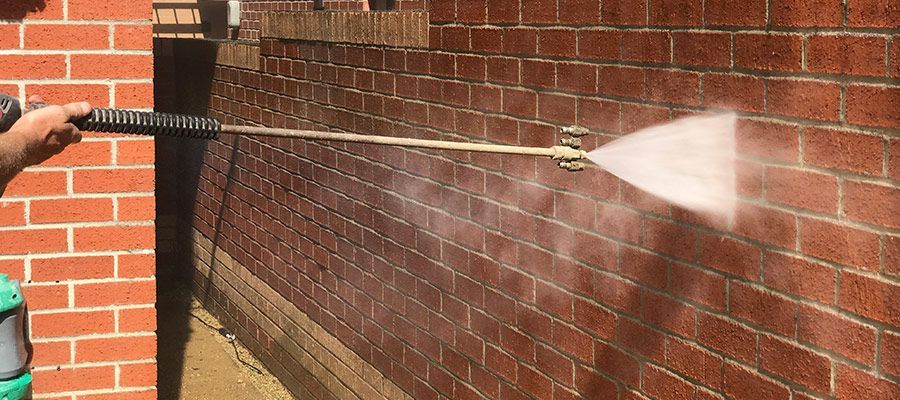

Sandblasting is a method where media materials such as sand, glass beads, or steel grit are blasted at high speed using compressed air through a nozzle onto the surface that requires treatment. This powerful and efficient technique cleans surfaces and prepares them for subsequent operations like painting or coating. The choice of abrasive material depends on the type of surface and the desired outcome.

Cleaning Applications

In industrial cleaning, sandblasting is second to none for removing dirt, rust, scale, and old paint from various surfaces. Its effectiveness makes it an indispensable tool in industries such as shipbuilding and maintenance, automotive restoration, and infrastructure refurbishment. Unlike chemical cleaning methods, sandblasting does not rely on potentially harmful chemicals, making it an environmentally friendlier choice.

Deburring Applications

Deburring is the process of removing small imperfections and sharp edges from metal parts after machining. Sandblasting provides a swift and uniform solution to this necessity, ensuring that parts fit together perfectly and operate smoothly. This is crucial in high-precision industries like aerospace and automotive manufacturing. Sandblasting's ability to access hard-to-reach areas and perform a thorough job makes it invaluable for complex geometries.

Surface Preparation

Surface preparation is a critical step in many manufacturing and construction processes, as it significantly influences the final product's quality and longevity. Abrasive sandblasting efficiently removes contaminants and creates a rough surface texture, enhancing the adhesion of coatings such as paint, rubber, or ceramic. This application is widely employed in pipelines, tanks, and other industrial fabrications to ensure coatings adhere properly, thereby extending the life of the equipment.

Safety Considerations

While sandblasting is highly effective, it also requires strict adherence to safety protocols. Operators must wear protective gear, including respirators, gloves, and protective eyewear, to safeguard against inhaling dust and other particulates. Additionally, proper ventilation is crucial in indoor settings to prevent the accumulation of airborne particles.

Environmental Impact

The environmental impact of sandblasting is a concern; however, technological advances have led to the development of more sustainable practices, such as using recycled glass or organic materials and improved containment methods. These practices help minimise the ecological footprint of sandblasting operations.

Sandblasting is a powerful and versatile technique used extensively in industrial cleaning, deburring, and preparing surfaces. Its ability to deliver efficient and effective results makes it a preferred choice in various applications. Choosing a specialist with a proven track record is crucial for companies seeking reliable and professional sandblasting services.

For those needing top-notch industrial sandblasting solutions, remember that choosing experienced providers like ours at Sandblasting Specialists ensures that your industrial components are treated with the highest standards of quality and care. We bring expertise, precision, and safety to every project, making us the first choice for your sandblasting needs. Simply search "sandblasting near me" on the internet to find us!

Check out our latest GBP update about the industrial applications of sandblasting.

You might also like

Service Areas

Give us a call today!