Your Complete Guide to Wheel Sandblasting for Restoration Work

When it comes to restoring or customising a vehicle, every detail counts – especially the wheels. Whether you’re a hobbyist working on a weekend project or a professional in the automotive industry, preparing your wheels correctly is essential. This process ensures your wheels are stripped of old paint, rust, and grime, providing the perfect base for a smooth, lasting finish. From improving durability to enhancing appearance, understanding how sandblasting works can help you make informed decisions for your next project.

What is Wheel Sandblasting?

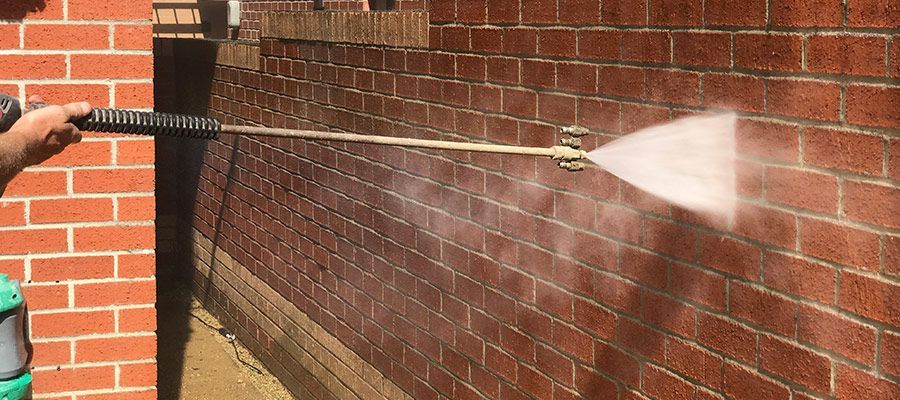

Wheel sandblasting is a process that involves propelling abrasive material at high pressure to clean or prepare the surface of a wheel. It’s commonly used to strip away layers of paint, corrosion, or contaminants that would otherwise interfere with new coatings or treatments. The process leaves the wheel with a clean, roughened surface that’s ideal for powder coating or repainting.

Step-by-Step: How the Wheel Sandblasting Process Works

Understanding the detailed process of this type of sandblasting helps you appreciate the precision and care involved in each stage. Here's a step-by-step breakdown of how professionals typically handle the task:

1. Initial Inspection and Cleaning

Before any blasting begins, the wheels are inspected for damage, cracks, or deformities. They are then thoroughly cleaned to remove dirt, grease, or brake dust. This step is critical, as contaminants can reduce the effectiveness of the blasting process.

2. Masking and Preparation

Parts of the wheel that should not be blasted, such as valve stems or certain centre caps, are masked off to avoid damage. Professionals often use high-heat masking tape and rubber plugs to ensure protection.

3. Sandblasting the Surface

Using specialised equipment, abrasive media like aluminium oxide or glass beads are blasted onto the wheel's surface at high speed. This removes paint, rust, and other residues efficiently. Adjustments in pressure and nozzle distance help to tailor the blasting process based on the wheel's material and condition. If you've ever searched for wheel sandblasting near me, you'll notice many service providers offering various types of blast media depending on the job's requirements. Choosing the right operator is crucial for preserving the integrity of the wheel.

4. Final Inspection and Finishing

After blasting, the wheel is carefully examined for a consistent finish. If needed, a second round may be performed to cover any missed spots. The wheel is then ready for powder coating, painting, or polishing.

Key Benefits of Sandblasting Wheels

There are numerous reasons why auto enthusiasts, metal fabricators, and industrial experts rely on sandblasting when working with wheels. Some of the most important benefits include:

Restores Old or Damaged Surfaces

Wheels affected by road grime, rust, or chipping paint can be completely revived. Sandblasting strips them back to a raw, clean metal state without using harsh chemicals.

Improves Coating Adhesion

One of the biggest advantages is the enhanced adhesion for paint or powder coat. A properly blasted surface ensures that coatings bind securely, reducing the chance of peeling or flaking over time.

Cost-Effective and Efficient

Compared to manual sanding or chemical dipping, sandblasting is quicker and often more economical. While sandblasting wheels cost can vary depending on the service provider and wheel condition, it generally offers excellent value for long-term durability.

What to Know Before Getting Your Wheels Sandblasted

Although sandblasting is a fantastic method for preparing your wheels, there are a few things to consider to ensure the best outcome:

Know Your Wheel Material

Not all wheels are created equal. Aluminium alloy wheels, for example, require careful handling to prevent pitting or surface damage. Professionals adjust pressure and abrasive types based on material.

Ask About Experience

Whether you're an enthusiast or a business seeking consistent results, experience matters. Look for providers who specialise in automotive applications and have positive customer reviews. A quick online search for sandblasting services in your area will yield a wide range of options. It’s worth taking the time to compare services and techniques before making a decision.

Equipment Quality Matters

The type of equipment used can make a significant difference. An industrial-grade sand blaster with proper nozzle control and dust filtration is essential for achieving a uniform, professional finish.

Is Wheel Sandblasting the Right Choice for You?

In most cases, yes. If your wheels are structurally sound but visually tired or corroded, sandblasting can be a game-changer. It’s especially ideal for:

- Car restoration projects

- Prepping for powder coating or custom paint jobs

- Removing stubborn corrosion or brake dust build-up

- Achieving a clean, smooth base layer without damaging the metal

For those in industries like automotive manufacturing or restoration, this process is often part of standard procedure to guarantee surface cleanliness and finish quality.

Wheel sandblasting is a tried-and-tested method for restoring wheels to their best condition. From removing rust to preparing a perfect surface for coatings, it delivers a professional-grade result that’s hard to achieve with traditional methods. Whether you're a seasoned professional or a car enthusiast embarking on a new project, understanding the process ensures you get the most from your investment.

As long as you work with a skilled operator, sandblasting offers a safe, effective, and visually satisfying outcome.

At Sandblasting Specialists, we offer professional, high-quality sandblasting services tailored to a wide range of industries — from automotive and marine to construction, oil and gas, and metal fabrication.

Here’s why our clients trust us:

- Precision Workmanship: Our team uses top-tier equipment and proven methods to ensure flawless surface preparation every time.

- Industry Experience: With years of experience in automotive restoration and industrial applications, we understand the importance of protecting both aesthetics and structural integrity.

- Customer-Focused Service: We listen to your needs, provide clear timelines, and deliver consistent results — whether you’re restoring a classic car or prepping parts for manufacturing.

- Health & Safety Commitment: We operate in fully controlled environments to reduce airborne contaminants and ensure safety for our staff and customers.

Whether you're an enthusiast, a business, or a restorer working with delicate or complex materials, we have the expertise you can rely on.

Check out our latest guide on X on

wheel sandblasting for restoration work!