Environmental Considerations in Sandblasting

In the bustling industrial sectors of Leeds and Bradford, sandblasting remains a pivotal process for cleaning and preparing surfaces. While this method is efficient and effective, it's not without its environmental challenges, primarily dust generation and containment. This comprehensive guide explores the essential environmental considerations in sandblasting, focusing on dust control and containment solutions that balance performance with sustainability.

The Environmental Impact of Sandblasting

Sandblasting has revolutionised surface preparation, easily stripping away old paint, rust, and other materials. However, this process can unleash a significant amount of particulate matter into the environment, leading to air quality degradation and potential health risks. Recognising the environmental footprint of sandblasting is the first step towards adopting more sustainable practices.

Dust Control Measures in Sandblasting

Effective dust control is paramount in mitigating the environmental impact of sandblasting. Here are some innovative solutions tailored for the Leeds and Bradford sandblasting community:

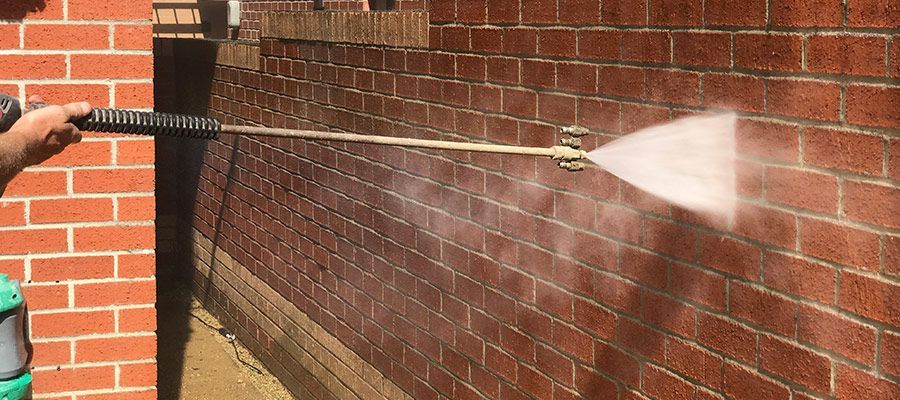

Wet Sandblasting Techniques

Wet sandblasting integrates water into the blasting process, significantly reducing dust emissions. This method captures dust particles and prevents them from becoming airborne, offering a cleaner and more environmentally friendly alternative.

High-Efficiency Particulate Air (HEPA) Filters

HEPA filters can capture very fine particles, making them an excellent addition to sandblasting equipment. They ensure that the exhaust air is clean, reducing the overall environmental impact.

Enclosed Blasting Chambers

Using enclosed chambers for sandblasting operations can prevent dust from escaping into the atmosphere. This containment solution is particularly effective in urban areas like Leeds and Bradford, where environmental regulations are stringent.

Containment Solutions for Sandblasting

Beyond dust control, containing the blasting area is crucial to prevent environmental contamination. Containment solutions include:

Tarpaulin Coverings

Heavy-duty tarpaulins can enclose the sandblasting area, capturing dust and debris. This method is cost-effective and adaptable to various project sizes.

Temporary Enclosures

Custom-built temporary enclosures offer a more robust solution for containing abrasive blasting operations. These structures can be designed to fit the specific needs of each project, ensuring maximum containment.

Vacuum Recovery Systems

Vacuum recovery systems collect blasted material and dust directly from the blasting site, preventing environmental dispersion. These systems are highly efficient and promote a cleaner working environment.

Regulatory Compliance and Best Practices

Adhering to environmental regulations is crucial for abrasive sandblasting businesses in Leeds and Bradford. Familiarising oneself with local and national environmental laws ensures that sandblasting practices are sustainable and legally compliant.

For sandblasting in Leeds and Bradford, embracing environmental considerations is a regulatory requirement and a commitment to sustainable practices. By integrating dust control and containment solutions, businesses can ensure their operations are both effective and environmentally responsible.

Sandblasting Specialists is your go to sandblasting company. Our team of skilled sandblasters are always available to answer the questions and inquiries you have. Simply search "sandblasting near me" on the internet to find us!

To know more, read our latest GBP update about the environmental considerations in

sandblasting.