Industrial Sandblasting: Key Applications and Benefits for Businesses

Industrial sandblasting has become an essential process across various industries, providing a fast and efficient way to clean, restore, and prepare surfaces. From metal fabrication to construction, industrial sandblasting is vital in maintaining equipment and enhancing surface quality. In this article, we’ll explore what industrial sandblasting involves, its primary applications, and the benefits it offers businesses aiming for durability and efficiency.

What is Sandblasting?

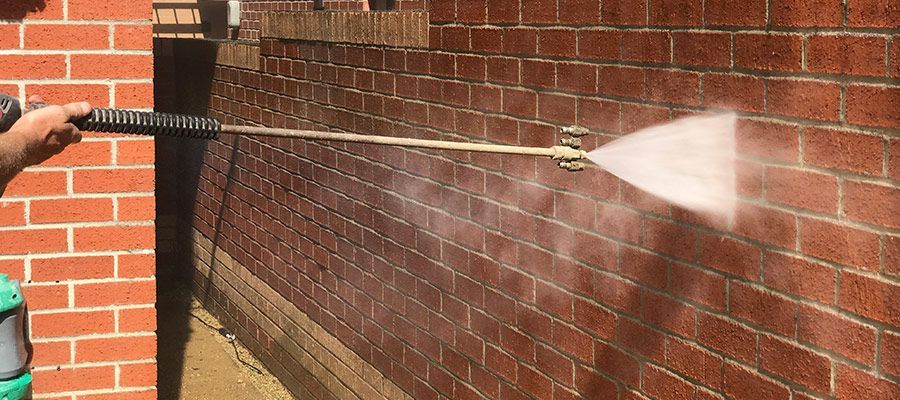

Sandblasting, also known as abrasive blasting, is a method that uses compressed air or steam to propel fine particles of sand or other abrasive materials at high speed onto a surface. This process effectively removes rust, paint, dirt, and other contaminants from materials, leaving them clean and primed for further treatment. The sandblasting technique can vary based on the specific material and project needs, using abrasives such as glass beads, steel grit, or aluminium oxide.

Key Applications of Industrial Sandblasting

1. Metal Surface Preparation

One of the primary applications of industrial sandblasting is metal surface preparation. When metals need to be painted or coated, it’s essential that they have a clean, even surface to ensure good adhesion and finish quality. Sandblasting removes impurities like rust, old paint, and residue, creating a smooth, ready-to-treat metal surface. This process is widely used in automotive, shipbuilding, and metal fabrication industries where surface precision is crucial.

2. Rust and Paint Removal

Over time, surfaces can accumulate rust, old paint, and other deteriorating coatings that compromise both appearance and structural integrity. Industrial sandblasting is an efficient solution for removing these layers and restoring surfaces to their original state. This application is common in heavy industries where machinery and metal structures are frequently exposed to harsh conditions.

3. Machinery and Equipment Maintenance

Regular maintenance of machinery and equipment is essential for optimal performance and longevity. Industrial sandblasting can clean hard-to-reach areas and remove built-up grime or residue without the need for harsh chemicals. This is especially valuable in industries like manufacturing, mining, and transportation, where machinery endures high levels of wear and tear.

4. Concrete Surface Cleaning

In construction and building maintenance, industrial sandblasting is also applied to concrete surfaces. Whether for removing graffiti, preparing concrete for repainting, or simply giving the surface a fresh appearance, sandblasting is a practical and efficient method for achieving a smooth, clean result. This process is widely used in preparing concrete walls, pavements, and other structural elements.

Industrial and Commercial Sandblasting Services

At Sandblasting Specialists, we offer a comprehensive range of industrial and commercial sandblasting services tailored to meet the unique needs of various businesses. Our services include:

- Industrial Sandblasting: From metalwork to concrete surfaces, we provide high-quality sandblasting for industrial applications, ensuring that surfaces are cleaned and prepared for further treatment.

- Commercial Sandblasting: Suitable for commercial premises, we offer targeted sandblasting services to help restore and maintain surfaces in retail, office, and commercial environments.

- Rust Removal: A specialised service to remove rust and restore metal surfaces, preserving their structural integrity and aesthetic appearance.

- Paint Stripping: Efficient paint removal for surfaces that need recoating or refurbishment, including walls, machinery, and more.

- Plant and Machinery: Regular sandblasting for heavy-duty plant and machinery ensures they remain in optimal condition, reducing wear and tear.

- Trucks and Trailers: Sandblasting for vehicles, including trucks and trailers, is available for businesses in logistics and transport, enhancing durability and visual appeal.

- Site Cleaning and Spillages: Our sandblasting services extend to site cleaning, including spillages, to keep work areas safe and compliant with environmental regulations.

Benefits of Industrial Sandblasting for Businesses

1. Enhanced Durability

Sandblasting extends the durability of surfaces and equipment by eliminating contaminants that can cause corrosion and degradation. By removing these harmful layers, businesses can improve the lifespan of their equipment and materials, leading to cost savings in the long run.

2. Cost-Effectiveness

Compared to manual cleaning methods, sandblasting offers a quicker and more effective solution. Businesses benefit from the time saved, which reduces labour costs and allows for faster project completion. This cost-effective approach is ideal for businesses looking to keep maintenance costs down while ensuring thorough cleaning.

3. Time Efficiency

Sandblasting is highly efficient, allowing large areas to be cleaned in a relatively short time frame. This is especially beneficial for projects on tight schedules or businesses where downtime needs to be minimised. The fast pace of sandblasting ensures that surfaces are cleaned and prepared swiftly, allowing the next stage of production to commence without delay.

4. Environmentally Friendly

Unlike some cleaning methods that rely on harsh chemicals, sandblasting is an environmentally friendly option. With no need for toxic chemicals, sandblasting reduces the risk of hazardous waste and limits environmental impact. In many cases, materials used in sandblasting can be recycled, further supporting sustainability efforts in various industries.

Safety and Compliance in Industrial Sandblasting

Sandblasting requires adherence to strict safety and compliance standards. The process involves high-speed particles, which can pose health and safety risks if not managed properly. Professional sandblasting services ensure that operators are fully trained and that equipment meets all necessary safety regulations. By choosing a certified sandblasting provider, businesses can be confident that safety protocols are followed, ensuring a safe work environment for everyone involved.

Industrial sandblasting is an invaluable process that serves a range of industries, from manufacturing and construction to transportation and metal fabrication. Its primary applications—such as surface preparation, rust removal, equipment maintenance, and concrete cleaning—offer businesses a fast, effective, and environmentally conscious solution. By investing in industrial sandblasting, businesses can achieve enhanced durability, lower maintenance costs, and improved efficiency, making it an essential part of their maintenance and preparation processes.

At Sandblasting Specialists, we bring years of expertise and a commitment to excellence to every project we handle. Our team of skilled professionals uses advanced sandblasting equipment to ensure precise and consistent results, tailored to meet the specific needs of your business. We prioritise safety and compliance, following industry standards to provide a reliable, efficient, and environmentally conscious service. By choosing Sandblasting Specialists, you can trust that your surfaces will be treated with the utmost care, ensuring optimal durability and performance.

Check our GBP update about the key applications and benefits of industrial sandblasting for businesses.