Sandblasting vs. Shot Blasting: Which is Better for Your Project?

When preparing surfaces, selecting the right technique is crucial for achieving the best results. Two popular methods are sandblasting and shot blasting, each offering unique benefits depending on the project requirements. In this post, we'll explore these two techniques to help you determine which is better suited for your needs, particularly if you're based in Leeds or Bradford.

What is Sandblasting?

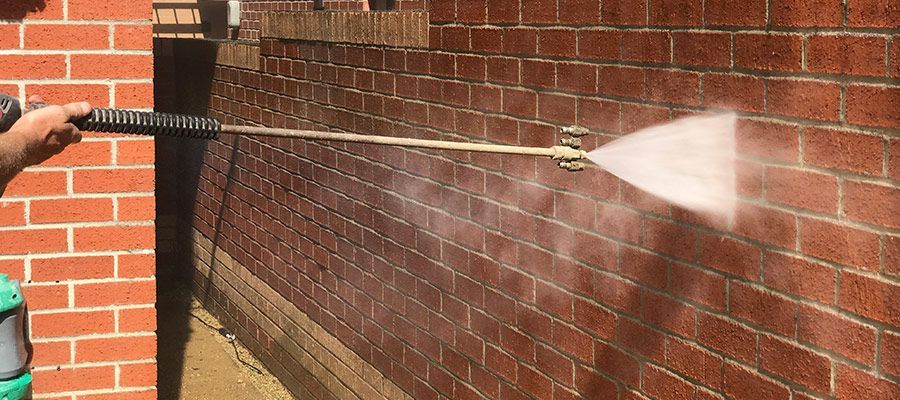

Sandblasting involves propelling fine particles, usually sand, at high speeds to clean or etch surfaces. This technique is widely used for removing paint, rust, and other contaminants, making it ideal for restoration and preparation work.

Common applications of sandblasting include:

- Building Restoration: Removing old paint or graffiti from historic buildings like Leeds Town Hall or Bradford's Alhambra Theatre.

- Industrial Equipment: Cleaning machinery and equipment in local factories and warehouses.

Benefits of sandblasting:

- Versatility: Effective on various surfaces, including metal, concrete, and wood.

- Precision: Allows for detailed cleaning and preparation.

- Efficiency: Quickly removes contaminants and prepares surfaces for further treatment.

What is Shot Blasting?

Shot blasting, on the other hand, uses small steel balls or shots to clean and prepare surfaces. This method is particularly effective for larger, tougher surfaces and is commonly used in industrial settings.

Common applications of shot blasting include:

- Large Infrastructure Projects: Preparing surfaces for painting or coating in projects like refurbishing bridges and overpasses around Leeds and Bradford.

- Automotive Industry: Cleaning and strengthening metal parts used in vehicles.

Benefits of shot blasting:

- Durability: Provides a stronger, more durable surface finish.

- Consistency: Delivers a uniform surface texture.

- Efficiency: Ideal for large-scale projects with extensive surface areas.

Sandblasting vs. Shot Blasting: A Comparative Analysis

Choosing between abrasive sandblasting and shot blasting depends on several factors:

- Efficiency: Shot blasting is generally faster for large surfaces, while sandblasting is more precise for detailed work.

- Cost: Sandblasting can be more affordable for smaller projects, whereas shot blasting is cost-effective for larger areas.

- Surface Finish: Shot blasting provides a rougher finish, suitable for heavy-duty applications. Sandblasting offers a smoother finish for detailed work.

- Environmental Impact: Sandblasting can produce more dust and requires proper containment, while shot blasting has less environmental impact with reusable media.

Local considerations in Leeds and Bradford:

- Weather Conditions: The often damp climate in Leeds and Bradford means surfaces can be more prone to rust, making shot blasting a better option for preventing corrosion.

- Types of Buildings: Historic buildings in Leeds and Bradford, like the Leeds Corn Exchange or Bradford's City Hall, often require a gentler touch of sandblasting for restoration.

Factors to Consider When Choosing Between Sandblasting and Shot Blasting

When deciding on the appropriate method, consider the following:

- Type of Surface Material: Sandblasting is gentler and better for delicate surfaces, while shotblasting is ideal for tough metal surfaces.

- Project Scale: For large-scale projects, shot blasting may be more efficient and cost-effective.

- Desired Finish: If a smoother finish is required, sandblasting is the way to go.

- Environmental Concerns: Consider the environmental regulations and containment requirements in Leeds and Bradford.

Specific project examples:

- Restoration of Historic Buildings: Sandblasting can gently remove layers of old paint from historic landmarks like the Leeds Grand Theatre.

- Preparation of Industrial Surfaces: Shot blasting can prepare metal surfaces for repainting in local factories and industrial sites.

Both sandblasting and shotblasting offer unique advantages, and the choice between the two depends on the specifics of your project. Sandblasting is often the preferred method for intricate restoration work on historic buildings in Leeds and Bradford. For larger, industrial projects, shot blasting provides the durability and efficiency needed.

At Sandblasting Specialists, we bring local expertise and a deep understanding of the specific requirements in Leeds and Bradford. Our high-quality services are tailored to meet each client's unique needs, ensuring satisfaction with every project. We've successfully completed numerous projects in the area. Trust Sandblasting Specialists to deliver exceptional results for your next project.

Check our GBP update discussing the distinctions between sandblasting and shot blasting, as well as determining the optimal method for your project.