The Economics of Sandblasting: Cost Analysis and Budgeting

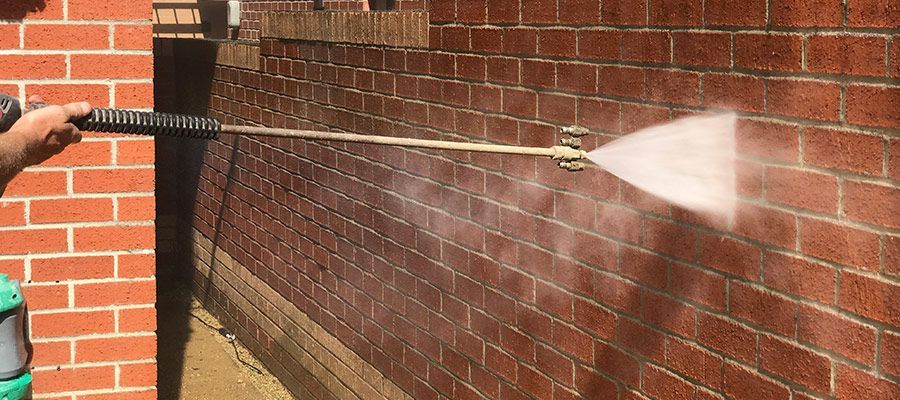

Sandblasting, also known as abrasive blasting, is an essential process in numerous industries, from manufacturing to restoration. This technique involves propelling abrasive material against a surface to smooth, shape, or clean it. Despite its widespread application, the cost-effectiveness of sandblasting projects remains crucial for businesses. This blog post will delve into the economics of sandblasting, offering a detailed cost analysis and providing practical advice for effective budgeting on projects.

Understanding the Costs Involved in Sandblasting

Equipment and Materials

The primary expense in sandblasting revolves around the equipment and materials used. Sandblasting machines vary widely in price, depending on their capacity, power, and whether they are manual or automated. Typical materials used in the process, such as sand, steel grit, or specialised abrasives like walnut shells, also contribute to the costs. These materials differ in price, with specialised abrasives generally being more expensive but necessary for certain finishes or substrate materials.

Labour Costs

Labour costs are significantly influenced by the complexity and scale of the project. Sandblasting is a skilled task that requires trained operators, especially for intricate work or surfaces that require a delicate approach. The cost will also vary depending on the location of the project and the prevailing wage rates in the region.

Compliance and Safety

Compliance with health and safety regulations is another cost factor that cannot be overlooked. Sandblasting generates a considerable amount of dust, which can be hazardous. Investment in protective gear for workers and environmental controls to prevent pollution can lead to additional costs but are essential for legal compliance and the safety of workers.

Utilities and Maintenance

The operation of

mobile sandblasting equipment requires utilities like electricity and water, which add to the operational costs. Maintenance of the equipment also incurs expenses, as parts wear out and need replacement due to the abrasive nature of the process.

Cost Analysis: Case Studies and Examples

To provide a clearer picture, we can examine a few case studies. For example, a small-scale sandblasting project, such as preparing a car for repainting, may cost from £500 to £1,000, while larger projects like cleaning the exterior of a commercial building can run into tens of thousands of pounds.

Budgeting for Sandblasting Projects

Initial Assessment and Quotation

Accurate budgeting begins with a thorough assessment of the project. Detailed quotations should include all potential costs, from materials to waste disposal. This transparency helps avoid unexpected expenses and ensures that the client is aware of the full scope of the project.

Contingency Planning

It is prudent to include a contingency fund in the budget, typically 10-20% of the total estimated cost, to cover unforeseen circumstances such as delays due to weather or additional preparation required on more deteriorated surfaces.

Long-Term Considerations

When planning a budget, it is beneficial to consider the long-term implications of abrasive sandblasting, such as the potential for reducing maintenance costs on a well-prepared surface or the longevity provided by using higher-quality abrasives.

Grit blasting is a cost-effective surface preparation and cleaning method when adequately planned and executed. A comprehensive understanding of the costs involved and meticulous budgeting ensures that projects are completed efficiently and economically.

For those seeking reliable and professional sandblasting services, choosing our company, Sandblasting Specialists, ensures that your project is handled with expertise and attention to detail. We are committed to delivering high-quality results while adhering to budgetary constraints and safety standards, making us your first choice for sandblasting in Leeds and Bradford area.

Check out our latest GBP update about the economics of sandblasting.